Compounding chambers are a part of the cleanroom family specifically used in the pharmaceutical industry. These chambers are used in sterile compounding pharmacies and are commended by pharmacy regulatory inspectors.

When it comes to designing a cleanroom for sterile compounding pharmacies there are various elements to consider to ensure it is up to standard against the strict regulations of the industry.

What types of products will be compounded in the cleanroom?

The answer to this question is key to designing your compounding chamber – one of the questions to consider is the type of preparations that be compounded:

- Non-hazardous sterile compounding preparations

- Non-hazardous non-sterile compounding preparations

- Hazardous sterile compounding preparations

- Hazardous non-sterile compounding preparations

Each type of compounding chamber (dependent on the type of preparations) has different conditions that must be maintained and therefore regulations which they must adhere to.

Other aspects that affect compounding chamber regulations

In addition to what is being compounded within the cleanroom, there are various other elements that will affect the regulations of the chamber. This includes:

- The types of preparations the cleanroom will be used to compound

- The geographical market in which the compounding facility operates

- The geographical market where the compounding preparations will be sold

The most common regulation that apply for compounding chambers in the UK is ISO 14644-1 – which recently superseded British Standard 5295.

When designing a compounding chamber the layout, HVAC systems and pressure differential are also important aspects.

Compounding cleanroom layout

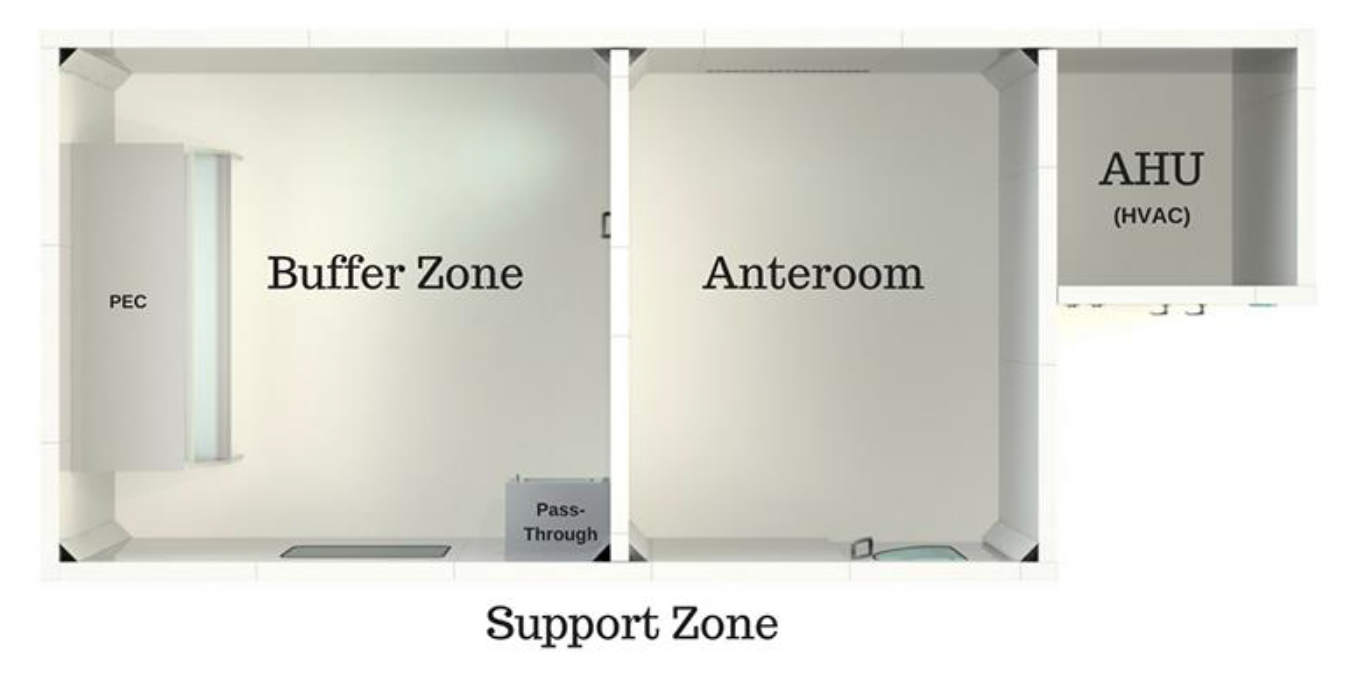

The typical layout of a sterile compounding chamber includes a:

- Buffer Zone / Clean Room: this area must be isolated from the rest of the pharmacy to reduce the risk of introducing contaminants. ISO class 7 must be maintained under dynamic operating conditions – find out more about ISO classifications here. Windows are commonly installed to reduce non-essential entry into controlled areas, whilst allowing pharmacists to see the activity within the room.

- Anteroom: this is a closed passage between the cleanroom and support zone. It is equipped with two door locks with a closing system that only allows one door to open at the same time to form an interlock. Everything that enters the cleanroom must be taken through the anteroom.

- Support Zone: this is an unclassified zone that is generally used for material storage, validation, entry of prescriptions etc.

Compounding chamber pressure differentials and HVAC systems

In non-hazardous compounding chambers – a highly important element is that there must be a pressure differential between the three zones. It’s crucial that the pressure gradient of the clean zone is greater than the anterooms, and the pressure gradient of the anteroom is great than the support zones.

Positive pressure will make air flow out of the room instead of into the room – preventing unfiltered air or particles from entering.

In hazardous compounding chambers – it’s the opposite. The pressure is negative to prevent the potentially contaminated air from escaping the room.

HVAC systems are key in the design of compounding chambers and cleanrooms as they control the supply of clean air. Another important element of cleanroom design is the humidity. Both elements need to be designed to consider how the conditions will be affected by the equipment and personnel working within the rooms.

If you are looking to design a cleanroom or compounding chamber for your business – MTCSS are here to help. No matter the size or complexity of the facility, our expert team will work with you to design a room that fits your processes and adheres to strict regulations and standards.

Get in touch with the MTCSS team by calling us on 01886 833381, email us at sales@mtcss.co.uk or fill in an enquiry form below.