Different Types of Cleanrooms & Their Uses

Cleanrooms are used in a wide range of industries that require high levels of control to manufacture and test products. Cleanrooms create controlled environments to reduce the levels of contamination within the air – therefore reducing the risk of contamination of airborne particles in the production process.

Measured and classified by the amount of particles within the air in a specific area, cleanrooms often use multiple levels of control to create the environment required, including: temperature control, humidity control, ventilation control, and contamination control.

Different industries and businesses will require different types of cleanrooms dependent on their processes, industry and business guidelines, and the classifications to adhere to. But what type of cleanrooms are there?

ISO Classified Cleanrooms

In the UK, cleanrooms are classified by BS EN ISO 14644-1 – this superseded British Standard 5295 – which is measured by particles per m³.

There are eight levels of ISO cleanrooms, measured from ISO 8 to ISO 1 – with 1 being the ‘cleanest’ – each dictate a specific maximum particle count per m³. The air in an ordinary, non-controlled room is approximately ISO 9.

Cleanrooms classified as ISO 8 or above will often require an airlock and specific parameters for personnel working with the cleanroom.

GMP Classified Cleanrooms

GMP classified cleanrooms must also be classified with an ISO number, but not all ISO cleanrooms need to be GMP classified.

GMP (Good Manufacturing Practices) regulates the manufacturing of sterile products and is commonly use in the production of pharmaceutical products. Cleanrooms with GMP compliancy have more stringent levels of control, with extra conditions required to meet the GMP Grade – graded A to D.

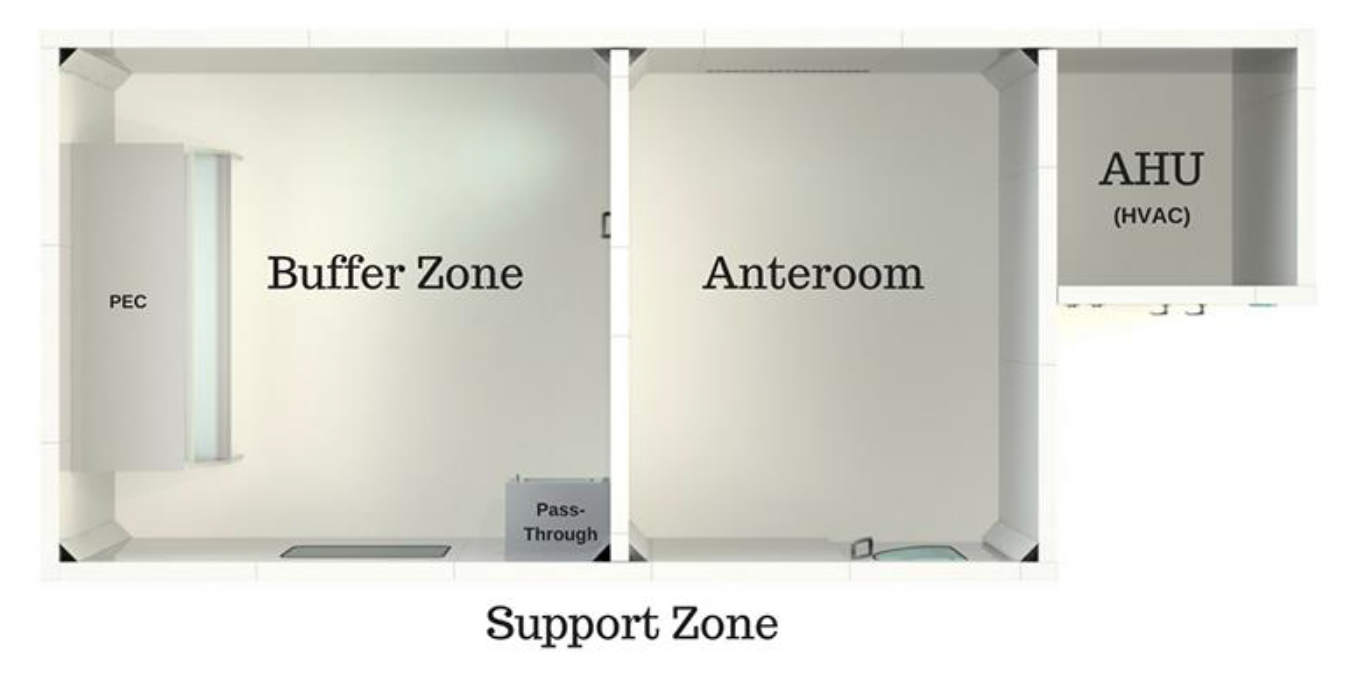

Compounding Chamber Cleanrooms

Compounding chambers are a type of cleanroom which are specifically used in the sterile compounding pharmacies and regulated by pharmacy regulatory inspectors.

There are a range of factors which impact the conditions of compounding chamber cleanrooms, including the type of preparations being compounded:

- Non-hazardous sterile compounding preparations

- Non-hazardous non-sterile compounding preparations

- Hazardous sterile compounding preparations

- Hazardous non-sterile compounding preparations

Other factors that affect the regulations of compounding chamber cleanrooms are:

- The types of preparations the cleanroom will be used to compound

- The geographical market in which the compounding facility operates

- The geographical market where the compounding preparations will be sold

Compounding chamber cleanrooms are also required to adhere to ISO 14644-1.

Modular Cleanrooms

Modular cleanrooms are designed to offer flexibility and easy installation compared to a ‘traditional’ cleanroom. Modular cleanrooms are typically assembled with prefabricated components, resulting in a simpler construction process.

Modular cleanrooms still offer a level of customisation as dictated by the customer’s requirements and can be designed to create small to large facilities when planned correctly.

There are various facets to consider and understand when designing a cleanroom for your business and industry, from the classification required and the regulations to adhere to – MTCSS are here to help.

If you’d like to discuss your cleanroom project or get a quote today, get in touch with our team. Call us on 01886 833381, email us at sales@mtcss.co.uk, or fill in an enquiry form below!