Pharmaceutical, medical and high-risk industries often use cold rooms or controlled areas to process, manufacture and store products. With these industries comes specific requirements, classifications and high levels of regulation – that is where cleanrooms come in.

MTCSS have worked within a variety of industries that have stringent regulations and requirements when it comes to temperature-controlled rooms. Our expert team can design and build cleanrooms to suit the exact requirements of the industry and specification.

What is a cleanroom?

Cleanrooms are temperature-controlled and atmosphere-controlled rooms which are built to adhere to specific classifications and requirements.

A cleanroom has controlled conditions to control and monitor low level pollutants (including dust, airborne microbes, aerosol particles and chemical vapours). The level of contamination is measured by the number of particles per cubic meter at a specified particle size.

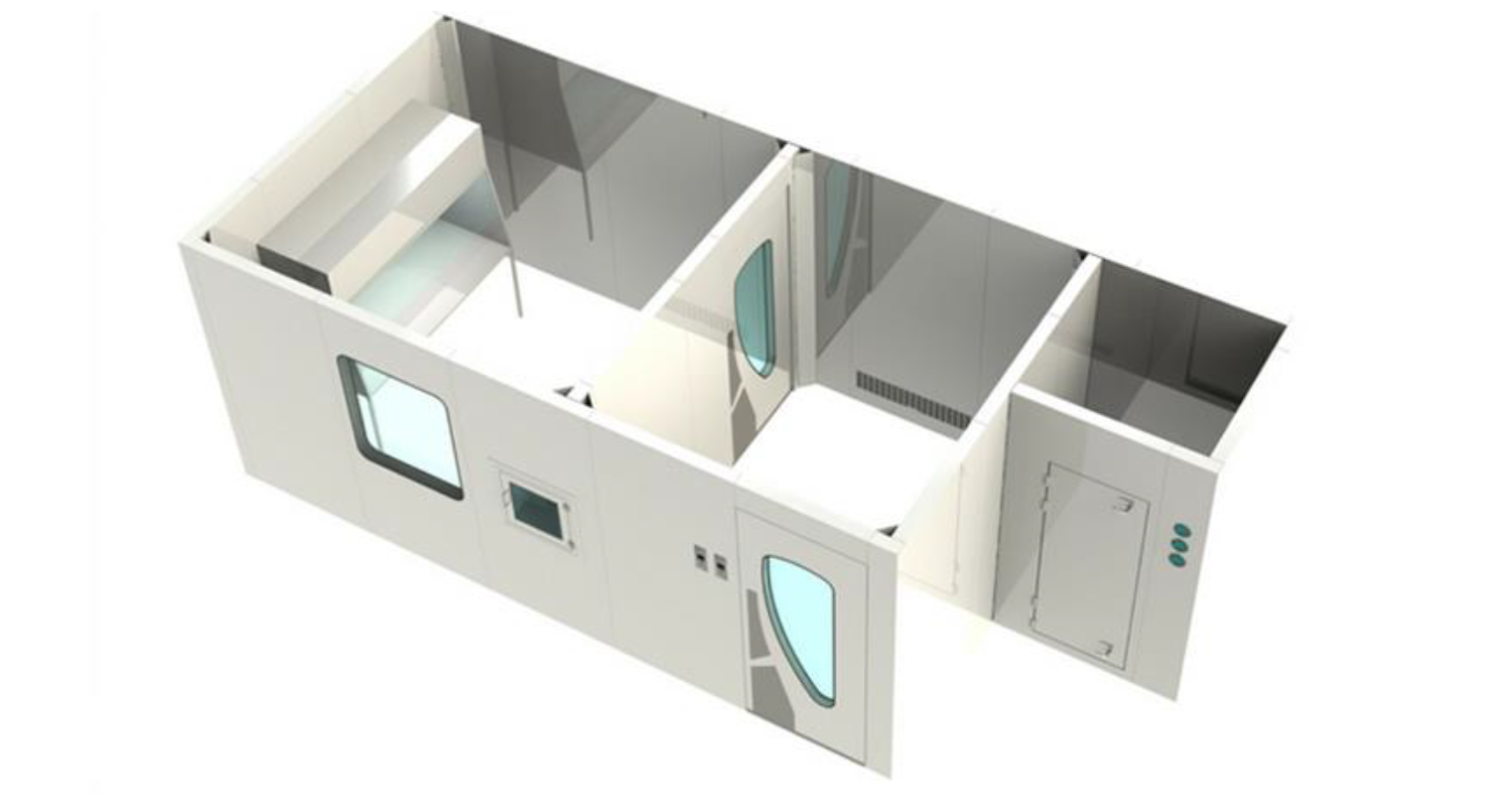

They are used in any industry where small particles or contaminants can negatively affect the manufacturing process. Similarly to cold rooms, they come in a variety of sizes and differ in complexity.

Cleanrooms are commonly used in manufacturing, pharmaceuticals, biotech, medical devices, life sciences, electronics & semiconductor fabrication, EV battery technology, in addition to engineering, automotive, aerospace, optics and the military.

Cleanroom Classifications

Due to cleanrooms having strict regulations on the levels of pollutants, they are required to adhere to specific classifications. These include:

- ISO 14644-1 which has now superseded British Standard 5295

- ISO 5 to ISO 9 class standard (dependent on the industry and application) – classifications go from Class 1 (being the ‘cleanest’) to Class 9 (being the ‘dirtiest’)

- GMP Grades A to D

If you are unsure which classifications you require in your cleanroom, don’t worry – a member of team can discuss the regulations specific to your requirements!

What MTCSS need to know to design your cleanroom

Designing a bespoke cleanroom to suit your industry and business requirements can be a more detailed process than designing a cold room. To help us understand the type of cleanroom for your application, we will work with you to answer a range of questions as below:

- What size cleanroom is required? Drawings can be helpful for this stage, even if they’re drawn on paper in pen!

- What are your door and window requirements?

- Do you need any antechambers / gowning rooms / airlocks / washing stations?

- What level of cleanliness is required?

- What processes will be taking place in the cleanroom?

- What classifications, regulations or standards must your cleanroom adhere to?

- Will there be any specific chemicals / solutions / solvents used?

- What temperatures, humidity and pressure ranges are required?

- What is the external ambient temperature surrounding the cleanroom?

- What equipment will be used within the cold room and what personnel will be working in it?

Of course if you are unsure about any of the questions above, our team would be more than happy to discuss the requirements regarding your cleanrooms in more detail.

You can get in touch with our team by calling us on 01886 833381, emailing us at sales@mtcss.co.uk or fill in an enquiry form here!